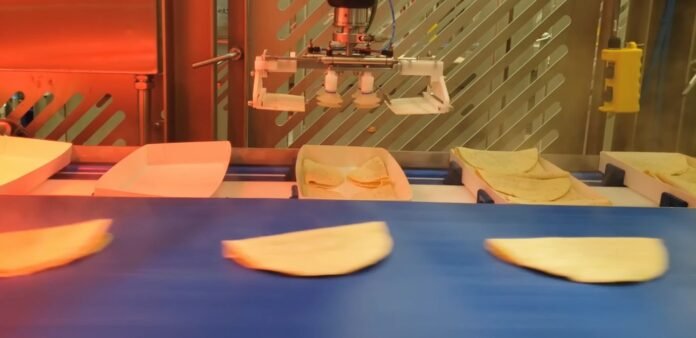

Fast-paced manufacturing lines increasingly depend on automation as labor challenges grow and accuracy expectations rise. Many facilities once struggled with inconsistent product handling, but modern technology now delivers dependable precision. Automated systems reduce slowdowns, strengthen consistency, and improve processing speed. This article explores how innovative equipment reshapes packaging performance and explains why advanced solutions support stable, long-term productivity across demanding industrial environments that require reliable handling, placement, and organized product movement.

Automation Elevates Handling Efficiency

Modern production environments rely on equipment capable of performing repeated tasks with controlled timing and consistent accuracy. Systems designed for continuous action reduce operational strain while maintaining predictable output quality. In mid-level performance assessments, specialists frequently analyze pick and place robots for their impressive handling capabilities, while detailed reviews highlight carton loading systems for improving line balance and ensuring structured product movement across high-demand manufacturing operations requiring dependable automation.

Precision Improves Product Placement

Accurate placement ensures each item reaches its intended position without misalignment or unnecessary delays. Facilities dealing with sensitive materials appreciate technology that reduces variability during fast operations. In mid-cycle evaluations, advanced pick and place robots earn recognition for delivering predictable placement accuracy, while assessments focusing on carton loading highlight smooth transitions that protect product orientation and maintain stable performance throughout demanding packaging sequences that rely heavily on timely and consistent movement.

Speed Supports Rapid Operations

High-speed manufacturing demands systems capable of handling increased throughput without compromising accuracy or stability. Many facilities lean on automation to meet rising consumer expectations. In mid-production analysis, experts often emphasize how pick and place robots support accelerated performance, while comprehensive studies on carton loading reveal enhanced cycle speeds that allow facilities to maintain competitive output levels even during challenging production surges influenced by market shifts.

Technology Reduces Labor Intensity

Advanced automation lowers reliance on repetitive manual labor and minimizes errors associated with operator fatigue. Machines built for long-term action deliver steady results while easing physical strain. In mid-level operational reviews, high-performing pick and place robots are acknowledged for reducing task repetition, while structured examinations of carton loading show improvements in workflow continuity, enabling smoother operations that maintain consistent results across intensive packaging environments with heavy daily workloads.

Integration Strengthens Production Flow

Efficient production requires seamless coordination among equipment to prevent delays and interruptions. Integrated systems support smooth transitions across multiple processing stages. In mid-section engineering evaluations, reliable pick and place robots contribute to synchronized material handling, and optimized carton loading ensures orderly product arrangement. These combined improvements establish strong production flow patterns that enhance manufacturing dependability across varied operations requiring multitiered automation and continuous precision.

Conclusion

Stable performance creates predictable outcomes, allowing facilities to maintain quality regardless of shifting production demands. Well-engineered systems bring harmony to large-scale tasks involving repeated movement and placement. Mid-range performance studies consistently feature pick and place robots for their long-term consistency, while advanced carton loading technology ensures organized material flow, reducing misalignment and reinforcing reliability across complex manufacturing lines focused on sustained efficiency and dependable output delivery.